Jul 01,2022

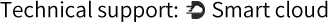

Nucleic acid purification instruments are designed to ensure high purity and yield of nucleic acids while minimizing contamination through a combination of advanced technologies, optimized protocols, and rigorous quality control measures. Here are the key ways these instruments achieve these objectives:

Key Strategies for Ensuring High Purity and Yield

Optimized Extraction Protocols:The instruments use standardized and optimized protocols tailored for different sample types (e.g., blood, tissue, cells) and nucleic acids (e.g., DNA, RNA).

Protocols are designed to maximize the binding efficiency of nucleic acids to purification matrices while minimizing the binding of contaminants.

Efficient Lysis and Binding:Effective lysis buffers and enzymes are used to completely break down cell membranes and release nucleic acids while protecting them from degradation.

Magnetic beads or silica columns with high binding affinity for nucleic acids ensure efficient capture, even from low-concentration samples.

Multiple Wash Steps:Multiple wash steps are incorporated to remove proteins, salts, lipids, and other impurities. These washes are carefully optimized to maintain nucleic acid integrity while removing contaminants.

Automated Handling:Automated systems minimize human intervention, reducing the risk of contamination. Precise liquid handling and robotic movements ensure consistent and reproducible purification processes.

Closed-system designs prevent exposure to the environment, further reducing the risk of contamination.

UV Decontamination:Some instruments are equipped with UV lamps for decontaminating surfaces and internal components, reducing the risk of cross-contamination between runs.

Aerosol-resistant Tips:Use of aerosol-resistant tips in automated pipetting systems prevents the formation of aerosols that can lead to cross-contamination between samples.

Separate Work Areas:Physical separation of different stages of the purification process (e.g., lysis, binding, washing, elution) within the instrument minimizes the risk of cross-contamination.

Quality Control MeasuresRegular Calibration and Maintenance:

Routine calibration and maintenance of the instrument ensure consistent performance and accuracy. Regular checks and servicing help identify and rectify potential issues before they affect results.

Use of Controls:Inclusion of positive and negative controls in each run helps monitor the performance of the purification process and identify any contamination or procedural errors.

Barcode Tracking:Automated barcode tracking of samples and reagents ensures proper identification and traceability, reducing the risk of sample mix-ups and contamination.

HEPA Filters:High-efficiency particulate air (HEPA) filters in the instrument’s ventilation system help maintain a clean working environment by trapping airborne contaminants.

Software Integration:Advanced software monitors the entire purification process, providing real-time feedback and error-checking. It ensures that all steps are performed correctly and consistently.

Chemical Decontamination:

Use of chemical decontaminants to clean the instrument’s surfaces and components between runs can help eliminate residual contaminants.

Specialized Reagents and Consumables

High-quality Reagents:

The use of high-purity reagents and buffers specifically designed for nucleic acid purification ensures that contaminants are minimized and nucleic acid integrity is preserved.

Single-use Consumables:

Single-use consumables, such as tips and tubes, prevent cross-contamination between samples and runs.

By incorporating these advanced technologies, optimized protocols, and rigorous quality control measures, nucleic acid purification instruments are able to achieve high purity and yield of nucleic acids while minimizing the risk of contamination.

Español

Español

Français

Français

Deutsch

Deutsch

عربى

عربى